Pharmaceutical products are subject to a rigorous series of tests before being released and for good reason.

The stability test is a procedure for product validation that must meet different specific standards in order to give the green light to products on the market.

The Stability Test for Pharmaceutical Products in the Stability Chamber

The stability test chambers are the best equipment to perform stability studies. Among the various applications, we can mention: pharmaceutical (products and packaging); medical (products and packaging); personal care (products and packaging); scientific and university research.

The stability chamber recreates the ideal environmental conditions of temperature, humidity and lighting required for the test. The temperature range is from 0 ° C to + 70 ° C, the humidity range from 10% RH to ± 90% RH and the lighting complies with ICH Q1A and ICH Q1B guidelines for stability testing of pharmaceutical products, in different conditions.

Pharmaceutical product testing may also require 21 CFR software that is FDA 21 CFR part 11 compliant.

The stability test is also used for accelerated aging tests, as it fastens this natural process on the different parameters of temperature, humidity and lighting.

Discover our stability test chamber for material testing

Perform

Extreme Testing

Discover the new series of Environmental Chambers for controlled climate testing

The International Standards for Stability Test on Pharmaceutical Products: ICH-Q1A and ICH-Q1B.

The field of pharmaceutical and cosmetic products is regulated internationally by the ICH , ie the international_use_conference"> harmonization of technical requirements for the registration of medicines for human use .

There are basically two standards to be observed for the stability test in a climatic chamber: the ICH-Q1A and the ICH-Q1B.

The ICH-Q1A regulates the procedures of all stability tests to be performed in a standard climatic chamber. The main parameters to be adjusted are those of temperature and humidity.

The ICH-Q1B, on the other hand, introduces the photostability test, ie the resistance of products to prolonged exposure to sunlight. For this reason, in addition to the temperature and humidity parameters, the climatic chamber must be equipped with fluorescent lamps or UV lamps, generally called ICH-lamps.

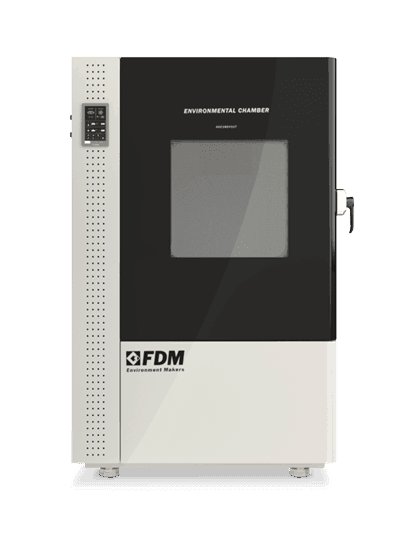

The FDM Stability Chamber

The FDM stability chambers provide an environment with uniform temperature and controlled humidity, equipped with an easy-to-use control system that saves time and guarantees a test without surprises and worries.

These chambers are ideal for stability testing for ICH Q1A pharmaceutical products, for determining the expiration date of a product, for packaging tests, accelerated aging tests and much more.

Our chambers can also be equipped with ICH-lamp to perform the photostability test as per ICH Q1B standard.

The Touch Screen controller can be customized to comply with FDA 21 CFR part 11 for ERES (Electronic Records and Electronic Signatures).

The controller is designed to simplify chamber operation including data logging, Ethernet control and monitoring from any device, alarm notification via email and/or text message, data file backup, full system security, audit trail, digital signatures, power recovery options, and more.

Stability Testing Chambers – Main Features:

- Temperature range 0°…+70°C

- Temperature stability of ±0.1…0.5°C

- Relative humidity control 10% to 90% ±3%

- Constant touch screen controller with CFR 21 software

- Data logging with network connection

- Inner lexan door with different compartments

- IQ/OQ certifications included

- GSM Module (optional)

- Best quality components, for a long-term simulation

- 100% made in Italy design and product

Stability Testing Chambers - Structure:

- External coating completely manufactured in white plastic coated galvanized steel; internal in AISI 304 stainless steel

- CFC and HCFC free polyurethane insulation

- Reversible doors equipped with self-closing hinges with 90-degree opening and replaceable magnetic seal plug

- Lexan-made internal door

- Steel grids, adjustable and with plastic coating

- Adjustable steel feet

CFR-21 Controller:

- Colour touchscreen display

- Peer to peer communications

- Modbus master/slave

- Profi bus master

- 10/100Mbps Ethernet

- Continuous and sequential control

- Multi-setpoint programmer

- Batch control

- USB support

- 21 CFR Part 11 auditor

- Data logging

- Open communications

- Alarm management

- Multi-language support

- Heat treatment application editor

Would you like to receive a quote or do you have questions about the product?

Contact us to receive more information about this Product.