Humans have used concrete for the past 5,000 years to build monuments that would stand the test of time.

The Egyptians used an early form of concrete to build the pyramids.

Romans used the compound to build the mighty aqueducts that allowed the rapid growth of their empire.

In 1824, Joseph Aspdin invented Portland Cement, which people would use to create some of the modern marvels we see today.

However, many of the ancient structures have either fallen or are in disarray because of the carbonation process in concrete.

What is carbonation, and what makes concrete so important? Read on to find out more about how manufacturers perform accelerated carbonation testing.

What Is Concrete?

Concrete is a composite material that consists of a matrix and a binder. The matrix is the aggregate of rocky material, generally limestone, granite, or gravel.

The binder is typically Portland cement; it holds the matrix together.

Based on Bogue’s equations, Portland cement contains between 60-67% CaO, 17-25% SiO2, 3-8% Al2O3, 0.5-6% Fe2O3, 0.1-4% MgO, 1.3-3% SO3, and 0.4 -1.3% Alkalies.

The chemical composition makes it durable, strong, and gives it the ability to lose plasticity and gain dense after the addition of water.

Water gets added to a dry powder and the aggregate, creating a mushy substance that the operator can manipulate into any shape he might need.

Structures that use Portland cement tend to use steel-bar reinforcement, creating a strong structure that can support a large amount of weight without bending or breaking.

However, the greatest threat to concrete structures is the carbonation process.

What Is the Carbonation of Concrete?

Carbonation is the chemical reaction between CO2 and the hydration compounds of cement in concrete structures.

The rate of carbonation depends on many physical characteristics, such as:

- On-site preparation

- Production and protection

- The design of the structure

There are other factors that play a role as well, such as the location of the structure and its exposure to contaminants.

Environmental factors, such as heat, rain, snow, and humidity, also play a role in carbonation.

What Does Carbonation Effect?

Carbonation goes deeper into concrete over time, generally at a rate proportional to the square root of time.

It only takes a few hours for the concrete surface to react with the CO2 in the air. The reaction can reach a depth of 1mm for dense concrete, and a 5mm depth for porous and permeable concrete.

This process causes a domino effect: firstly the reduction of the pH, lowering the natural alkalinity of concrete from pH13 to pH8.

The lower pH causes in turn the passivation layer around the steel to break down, exposing reinforcement steel to water and air, bringing the steel to rust.

Rusty steel then expands and puts force on the surrounding concrete.

The concrete eventually cracks, weakening the structure at an exponential rate.

Carbonation is a suspected reason, among many, of building failure in Lagos, Nigeria, an example of the damage that untested concrete can cause.

There is some good news, though.

Most people associate the carbonation process with the weakening of steel reinforcements and shrinkage, but not all effects are bad.

Carbonation also increases the compressive and tensile strength of concrete . The key is to find the right balance. To do this, you need accelerated carbonation tests.

What Is Accelerated Carbonation Testing?

In simple terms, this test is nothing more than a in-depth investigation to accelerate carbonation in a controlled environment .

It is a way for concrete professionals to test their product and determine its ability to last under certain conditions. This test is performed by checking the corrosion resistance. Needless to say, how a correct diagnosis of any issues can be fundamental on the safety and prevention sides.

Each test uses different parameters based on the type of conditions the concrete might face.

Some of these factors include:

-

- The concentration of CO2 gas — This is an especially important factor for concrete used in cities with large amounts of pollution

- Humidity — It is preferable for humidity to be at 50%-70%. There is less water with higher humidity. Water inhibits CO2 diffusion when it has higher concentration.

- Temperature — In hotter environments, there is a higher carbonation rate

- Water to cement ratio — this determines the pore system of the concrete and degree of hydration.

- Porosity and permeability

The problem is that it is difficult to control all of these variables without the proper equipment.

Any small change in these variables can lead to faulty test results or poor constructions.

In fact, even when researchers control these factors, there is still a difference between what is observed and what instead happens in a natural environment.

It is impossible to control for every possibility, but you can increase your odds with the right testing chamber.

Standards and Procedures for the Carbonation Test of Concrete

Recommended outlines for a concrete carbonation test procedure are:

- CO2 levels at 4%

- Relative humidity levels at 65%

- Temperature setting at 20°C

- Active CO2 control

- An efficient circulation fan

- A reference mix

- Calibration and adequate logging of results

It is recommended to condition samples in lab air for one month at 20-23°C.

If you are testing concrete with a protective coating, you will need to sandblast the samples before applying the protector. Allow them to “cure” for three days.

The ideal thickness for the test is between 40-50mm . This gives you enough material to gauge the results.

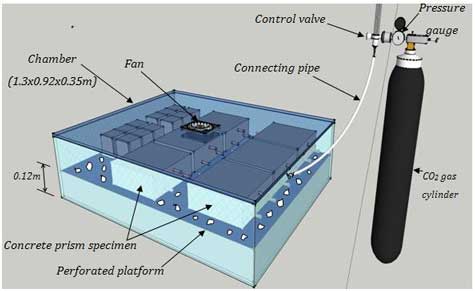

fig.1: Experimental set up for accelerated carbonation

Remedies for the carbonation of concrete

There are actually no easy remedies to solve issues related to the concrete that has undergone the carbonation process.

In most of the cases, the only solution is to operate with profound renovation where there have not already been more serious problems like collapses or irreparable damaging.

The only way forward is to try to prevent the issue by making all the necessary tests before the concrete is produced.

How to Find the Right Testing Chamber

Find below a few suggestions to understand what the main assessments during the investigation with a test chamber for concrete are.

- You will have to measure different variables for every type of concrete to be tested.

- You will also have to apply different values to these variables based on where the concrete gets used.

For example, you will have to increase the amount of humidity to test concrete used in Florida vs. Kansas. - You will also need to factor in the year-long heat and extreme summer heat Florida has vs. the cold of Kansas winters.

- You will need a testing chamber that allows making variations as the experiments demand them. You will also need one that is durable. The concrete carbonation test procedure is an ongoing process.

We Can Help You Find Your Ideal Chamber

We offer a wide range of testing chambers to meet any requirement.

You can choose between various sizes along with two different controllers, depending on whether you are running stability or dynamic testing.

Contact us and we will find the ideal chamber for your concrete carbonation tests