Composite materials are playing an increasingly central role in industrial research and development.

Lightweight, durable, and versatile, they offer innovative solutions in sectors such as aerospace, automotive, and energy.

In today's article, we'll explore the complexities of composite material testing and how to address them, especially with regard to environmental testing.

What is a Composite Material?

A composite material is made up of two or more components with different properties, combined to achieve superior performance over their individual components.

Typically, these fibers (such as carbon, glass, or aramid) are embedded in a polymer matrix that holds them together. This layered structure makes composites particularly strong relative to their weight, but also complex to analyze: interactions between the different phases can generate unpredictable behavior under stress.

How does Composite Materials Testing Work?

Testing a composite material isn't simply about breaking it to see how strong it is. It is necessary to evaluate their response to tensile, compressive, flexural, and impact stresses, as well as environmental conditions, as well as how they vary over time under real-world operating conditions.

The main difficulty lies precisely in their heterogeneous nature: a small variation in fiber arrangement or matrix quality can significantly impact performance.

This is why standardized and repeatable methods are used to obtain comparable and reliable results.

Perform

Extreme Testing

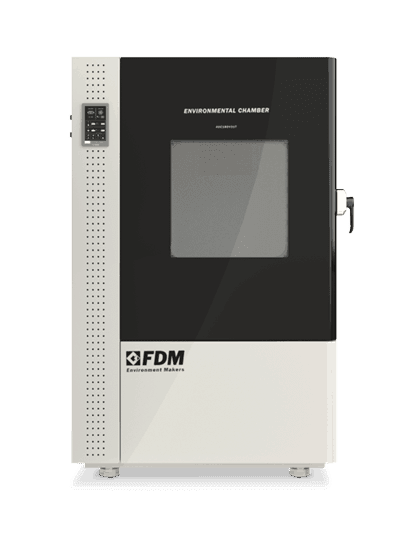

Discover the new series of Environmental Chambers for controlled climate testing

Environmental Testing of Composite Materials

In addition to mechanical stress, composites must often withstand extreme environments. Humidity, temperature fluctuations, sunlight, and chemical agents can degrade their properties over time.

To study their behavior under realistic conditions, laboratory instruments called environmental chambers are used.

In environmental chambers, key parameters such as temperature and relative humidity can be set, adjusted, and monitored in a hermetically sealed environment.

Among the most common procedures are accelerated thermal cycles, which alternate rapid excursions between -40°C and +180°C to assess resistance to thermal shock, or prolonged humidity tests with exposure to 95-98% relative humidity to identify delamination and swelling.

Another common test is accelerated aging under UV light, performed with xenon lamps t

These tests allow us to anticipate potential material failure and compare different formulations or production processes before putting them into service.

International Standards for Composite Materials Testing

Tests must be conducted in compliance with internationally recognized standards, which define methods, parameters, and acceptance criteria. Among the most widely used:

ISO 14125 – Flexural strength testing of polymer matrix composite materials

ISO 527 – Determination of tensile properties of plastic and composite materials

ASTM D3039 / IEC 60068 – Combined mechanical and environmental testing of materials and components

Following these standards is essential to ensure the validity of results and make them acceptable to certification bodies and industrial clients.

You cannot find the ideal chamber for your test?

Create your own environment, according to any test requirement

The FDM Environmental Chamber for Composite Material Testing

For over 70 years, FDM - Environment Makers has been designing practical and reliable solutions in the field of climate simulation.

Our environmental chambers are the ideal tool for testing composite materials.

Furthermore, our technicians are always available to listen to specific customer requests to design a customized environmental chamber that meets their needs.

Read the technical white paper below and don't hesitate to contact us!

Would you like to receive a quote or do you have questions about the product?

Contact us to receive more information about this Product.