The climatic chambers are built to perform a wide range of climatic tests on materials. Some of these tests are very specific, are designed for a certain category of products and require particular chambers.

The case we are examining today is that of the Burn-In Chambers for semiconductor tests.

What are Semiconductors

A familiar name only to engineers and computer scientists, semiconductors made headlines in the aftermath of the pandemic. We are in fact still in the midst of the biggest semiconductor crisis since their invention due to the production crisis following the various lockdowns.

Why are semiconductors so fundamental?

Science tells us that semiconductors are semimetals that can assume a resistivity higher than that of conductors and lower than that of insulators; resistivity is directly dependent on temperature.

Due to these very precious characteristics, semiconductors are used in electronics and more precisely in microchips and electronic boards.

In short, semiconductors are an essential component of an incalculable number of electronic products that we use every day. The burn-in test on semiconductors is a fundamental step to verify their reliability.

Perform

Extreme Testing

Discover the new series of Environmental Chambers for controlled climate testing

What is the Semiconductor Burn-In Test

Being the most delicate and at the same time most functional part of a lot of consumer electronics, semiconductors are subjected to a rigorous series of tests in the climatic chamber, including the one in the Burn-In Chamber.

The Burn-In test on semiconductors takes place in the early stages of the component's life to immediately check its resistance and lower the possibility of "infant mortality" of the product. This is an extreme climate test that subjects the semiconductor to thermal cycles (such as at 125 ° C for 168 hours) and environmental cycles (such as 20 cycles from -10 to 70 ° C).

Due to the extreme values

You cannot find the ideal chamber for your test?

Create your own environment, according to any test requirement

What are Burn-in Chambers

Burn-in chambers or burn-in ovens are the names given to all climatic chambers that are able to reach certain temperatures and therefore perform the Burn-in Test.

It should be noted that it is not a technical name and the most important thing is to check the technical characteristics of the machine.

For example, the chambers known as environmental chambers reach values

Burn-in ovens, burn-in chambers or environmental chambers: as they are called by the manufacturer, the important thing is that they can touch certain values.

To find out in detail the requirements of the test, we advise you to consult the international regulations in this regard, which can be found in the IEC / EN-60068-2 and IEC / EN-60068-3 standards.

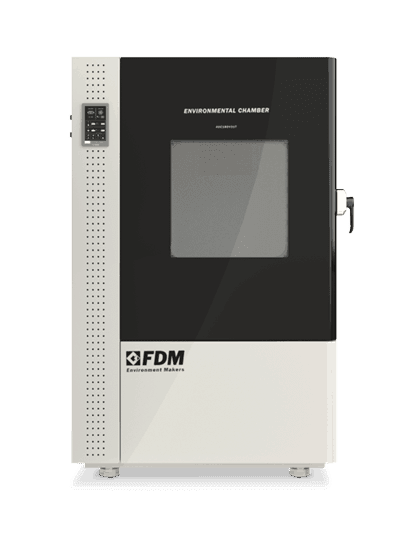

The FDM Environmental Chamber for Burn-In Test on Semiconductors

By virtue of the above, our FDM Environmental Chamber is the ideal tool for performing burn-in tests on semiconductors.

In addition to the maximum values

Each FDM climatic chamber also has a simple and intuitive interface that guides the operator at every stage of the process. To find out more, please do not hesitate to contact us.

Would you like to receive a quote or do you have questions about the product?

Contact us to receive more information about this Product.