All products are prone to loss of their capabilities and functions over time and that is natural. But some of these have manufacturing defects and formal flaws that lead to early malfunctions in the very first period of use.

To overcome this problem, manufacturers perform Environmental Stress Screening, often abbreviated with the acronym ESS.

Perform

Climate Stress

Discover the new series of Climate Chambers for controlled climate testing

Definition of ESS

Within the environmental stress screening there are a whole series of tests that stress the product in an extreme way in order to bring out defects and dysfunctions. These include thermal cycles in a climatic chamber but also physical tests that subject the sample to vibrations, pressures and torsions.

What is the ESS for?

As we have anticipated, the main purpose of the SSE is to reduce the so-called infant mortality of products. It has been studied that in the life cycle of a sample of untested products, failures occur mostly during the first times of use and then stabilize for a fairly long period and finally re-emerge after years of use have worn down most of the samples.

It is called the "Bathtub effect" due to the characteristic shape of the parabola that describes this trend on the Cartesian plane.

By subjecting the products to the ESS before marketing them, we intend to break down the first curve of the tank, the one in which all the products with inherent vices and manufacturing defects emerge.

Perform

Extreme Testing

Discover the new series of Environmental Chambers for controlled climate testing

What kind of sectors are involved in the SSE?

The ESS is a series of tests that are carried out mainly on electronic devices of various kinds. They range from consumer electronics to components that we can find almost everywhere and therefore involve industries such as automotive, aerospace engineering and the military sector.

In all these fields, it is clear that it is vital to eliminate any possibility of early malfunctions.

For this reason, the results of the environmental stress tests are regulated by a series of international bodies that prescribe the procedures to be implemented.

The ESS Standards

With regard to climate tests - which are a fundamental part of the broader ESS and of our direct competence - there are basically two standards to keep an eye on.

IEC 60068 which in all its sub-chapters covers all climatic and thermal tests on electronics in general. While, for the specific of the military sector, we must refer to the standards of the MIL-STD which are:

We have already written an article dedicated in particular to climate tests on electronic material and you can read it here.

You cannot find the ideal chamber for your test?

Create your own environment, according to any test requirement

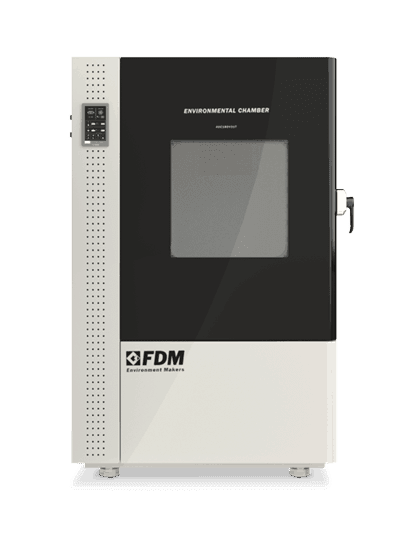

The ESS FDM Chamber

FDM environmental chambers can perform all major climatic and thermal tests found in the broader set of environmental stress screening.

With a temperature range that can reach -70 / 180 °, an adjustable humidity up to 98 ° and rising and falling rates of + 5 / -4 ° / min respectively, they are the perfect tool to solicit the necessary stresses to verify the infant mortality of electronic products.

For further questions or requests, please do not hesitate to contact us.

Would you like to receive a quote or do you have questions about the product?

Contact us to receive more information about this Product.