Sterilization is a essential and necessary process in many fields and especially in the medical-scientific one.

Nowadays, there are many methods to sterilize an object or an environment but one of the most effective remains hot air sterilization.

In the following article we will observe in detail the various types of hot air sterilization, the international standards that regulate the procedures and the best laboratory instruments capable of performing hot air sterilization.

What is Sterilization?

The history of modern sterilization can be traced back to the great Louis Pasteur, father of microbiology who worked in the second half of the nineteenth century.

When humanity began to better understand the existence of microorganisms and their danger, there was a need to develop a process that would completely eliminate their presence in very delicate activities, such as surgery.

But only in the following century, thanks to technological advancement, the first true modern sterilization techniques were developed, namely the complete elimination of microorganisms from an environment or an object.

Today a material is defined sterile if the chances of finding a microorganism are less than one in a million.

Among the various contemporary methods we find hot air sterilization.

Types of Hot Air Sterilization

The first field of application for hot air sterilization is the medical-scientific one, both to create a suitable environment for microbial culture and to sterilize medical instruments.

There are two types of hot air sterilization, both of which are very popular.

We speak of moist hot air sterilization when it is operated by means of flowing or saturated steam, with tools such as the Koch pot and the autoclave.

Generally, the temperature to be reached with this method is 90 ° and the procedures are regulated by ISO 17665-1: 2006.

Dry hot air sterilization, on the other hand, requires much higher temperatures.

Generally it is necessary that a temperature of 160 ° is reached for one hour or 180 ° for 30 minutes. Procedures specifications are outlined in ISO 20857: 2010.

To perform dry hot air sterilization, ovens, dryers, incubators and environmental chambers are used.

Perform

Extreme Testing

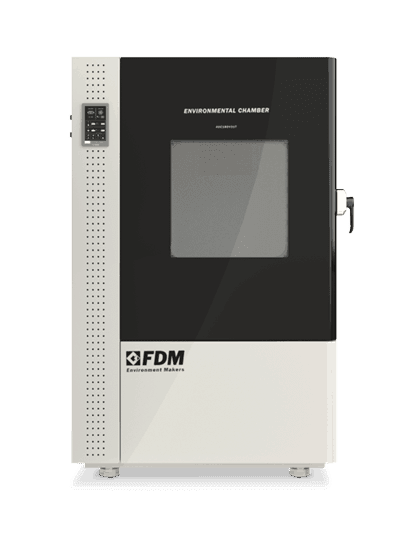

Discover the new series of Environmental Chambers for controlled climate testing

FDM Ovens for Hot Air Sterilization

FDM - Environment Makers has been producing laboratory instruments for over 70 years and, as far as dry hot air sterilization is concerned, we have two different products that perform this function.

On the one hand there are the FDM ovens and dryers, specialized in temperature control and capable of reaching extreme values

On the other hand, there are the FDM environmental chambers which reach 180 ° (therefore perfect for the standard procedure) and however have many other functions including relative humidity control and can be equipped to perform most of the climatic tests.

For further doubts and questions, please do not hesitate to contact us.

Would you like to receive a quote or do you have questions about the product?

Contact us to receive more information about this Product.