In addition to the climatic tests that we commonly deal with, many materials must undergo mechanical tests to verify their resistance before being put on the market.

Laboratory instruments that perform this type of testing are called universal testing machines and there are several types of them.

In the following article, we will see what the different types of universal testing machines are, what type of tests they perform and why they cannot be separated from climatic chambers.

What is the Universal Test Machine

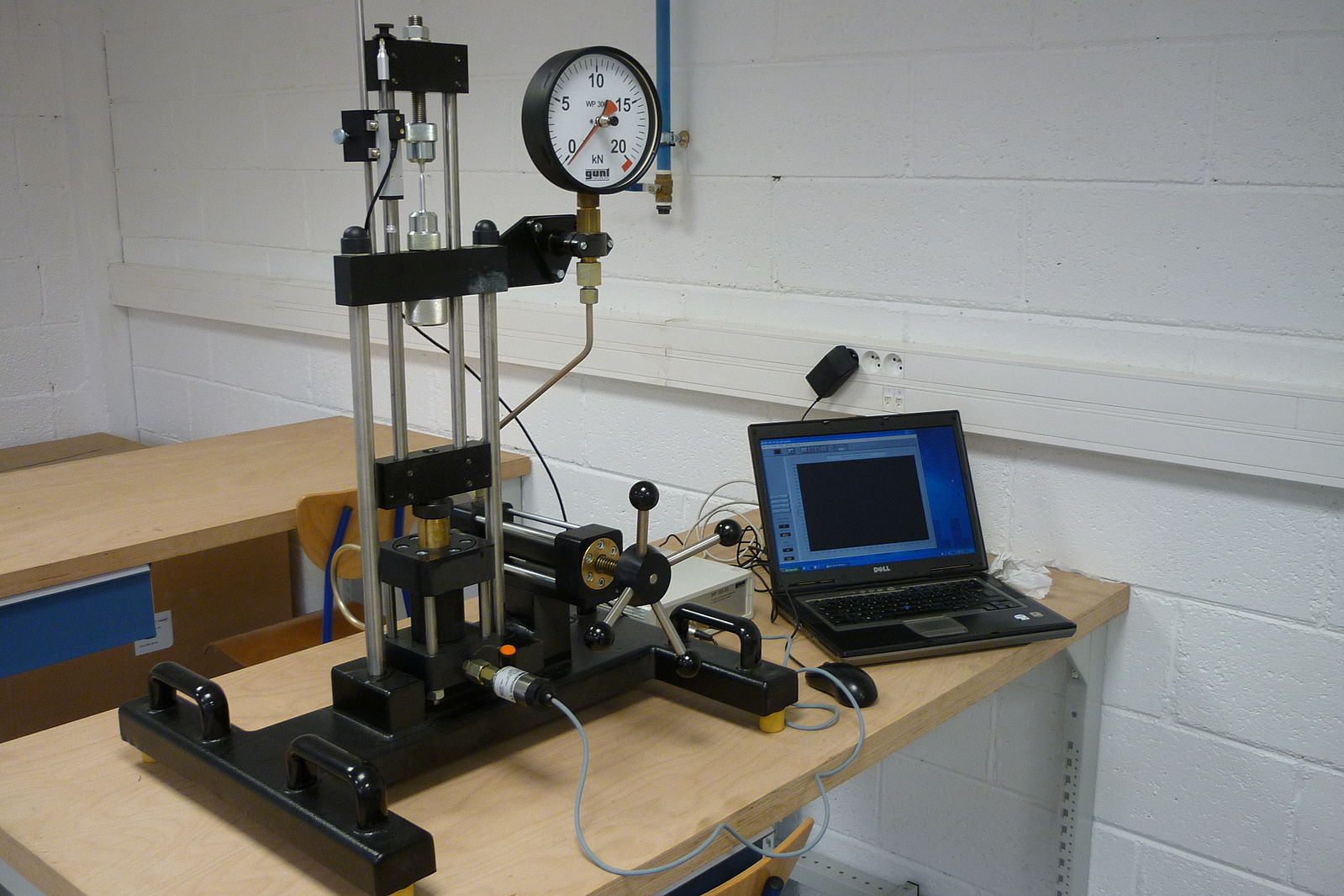

The universal testing machine is a laboratory instrument capable of impressing forces of various types and different intensities on materials. It is defined universal due to the wide range of possible uses but in the past, it was known more simply as a "traction machine" or "dynamometer".

As we will see, the structure of these machines can vary but generally include a frame that can be composed of one or two support columns. At the centre of the frame there is the mobile crossbar with an attached load cell which gives the controlled force to the sample t

Perform

Extreme Testing

Discover the new series of Environmental Chambers for controlled climate testing

How the Different Types of Universal Testing Machines are distinguished

There are three parameters to classify the different types of universal testing machines: operating principle, construction characteristics and intensity of the developable force.

Universal testing machines can have three different principles of operation:

- Hydraulic

- Electromagnetic

- Pneumatic

The most common ones are with the hydraulic principle, while those with the pneumatic principle are the rarest.

As far as construction features are concerned, universal machines vary greatly depending on the model and it is impossible to exhaustively summarize all the versions on the market. One of the fundamental differences, as anticipated, is the construction of the frame with one or two columns. Universal single-column machines are rarer and more limited in use.

Finally, the universal testing machines can be distinguished by the intensity of the developable force of the machine, which can vary from a few hundred N up to 1000 or more kN.

The Universal Test Machine Tests

The materials passing through the universal testing machine must undergo two main categories of tests: the compressive strength test and the ultimate tensile strength test.

The compression resistance test is generally carried out in a monoaxial regime and verifies the resistance of the materials to loads that tend to deform them and reduce their extension, or to compress them.

It is mainly used on concrete and is regulated by this international standard.

The ultimate tensile strength test, on the other hand, identifies the limit, in terms of force or external stress applied, beyond which material is definitively useless from the point of view of resistance.

It is divided in turn into 5 distinct tests, depending on the type of force impressed:

- Tensile breaking load

- Compression breaking load

- Straight bending breaking load

- Torsional breaking load

- Breaking load at shear stress

You cannot find the ideal chamber for your test?

Create your own environment, according to any test requirement

The FDM Environmental Chamber for the Conditioning Test in the Universal Machine

Some tensile strength and compression tests are called "conditioning" because they stress the material under certain environmental conditions.

These tests must be carried out by placing the universal testing machine in an environment in which it is possible to control the humidity and temperature parameters, that is a climatic chamber.

The FDM environmental chamber is the ideal tool to carry out this type of combined test and can be built in different sizes to accommodate all customer needs.

Don't hesitate to contact us.

Would you like to receive a quote or do you have questions about the product?

Contact us to receive more information about this Product.