Science must be able to guarantee the reliability of its results.

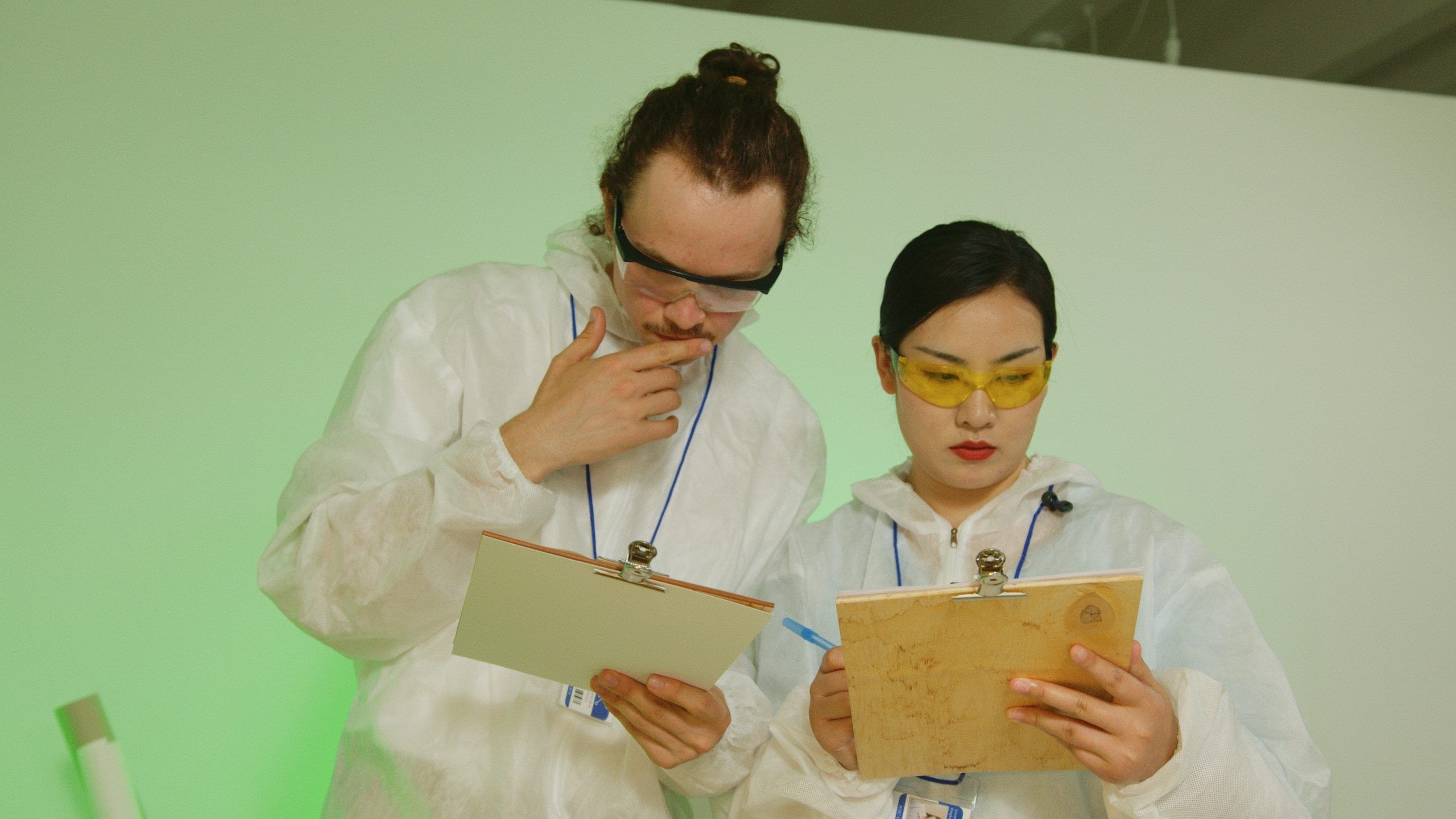

For this purpose, it is essential to define a good lab practice that can be verified by third-party observers and to testify the goodness of the tests.

Far from being a series of informal advice, the Good Laboratory Practice (abbreviated GLP) has merged into a series of internationally recognized documents that indicate all the factors that a certified laboratory must consider.

In the following article, we will look at the history of Good Laboratory Practice and a general overview of its principles.

History of Good Lab Practice

The need to establish criteria for the reproducibility of the experiments, and therefore the reliability of the results, has accompanied scientists since the beginning of the modern scientific revolution. The so-called "laboratory conditions" have always been at the centre of the concept of experiment, as a practice that takes place in a controlled environment isolated from external factors and human errors.

And yet, it was only in the seventies that documents were drawn up prescribing what these factors were that the laboratories and operators had to respect in order to ensure the reliability of the results.

Denmark and New Zealand were the first countries to introduce a shared national document on Good Laboratory Practice in 1972.

In 1976, the US Congress proposed a similar draft which was approved in the following years and finally signed by all OECD countries in 1981.

Perform

Climate Stress

Discover the new series of Climate Chambers for controlled climate testing

The 10 Points of Good Lab Practice

The OECD guidelines for Good Laboratory Practice can be found here.

The document is divided into ten points that isolate the various issues to be taken into account and are the following.

- Test Facility Organisation and Personnel

Each structure must have a clear organization chart with regards to those responsible for the laboratory and for verifying the application of these principles.

- Quality Assurance Program

The facility must have a clear quality assurance program that must be conducted and enforced by individuals not involved in testing.

- Facilities

This point outlines the minimum requirements that the facilities where the laboratories are hosted must have.

- Apparatus, Material, and Reagents.

This point outlines the minimum safety requirements for apparatus, materials, and reagents.

- Test Systems

The point is divided into physical/chemical tests and biological tests. Each test system must observe guidelines to ensure the isolation and reliability of the tests that are carried out there.

- Test and Reference Items

The point contains information on the correct storage of the samples, substances and other items involved in the experiment.

- Standard Operating Procedure

One of the most important points in which the drafting of a Standard Operating Procedure is imposed. It is described in its phases which articulate the points previously mentioned.

- Performance of the Study

Emphasizes the need to draw up a study plan before conducting the study in order to have independent evaluation parameters for the results.

- Reporting of Study Results

Indicates how to write the final report on the study conducted.

- Storage and Retention of Records and Materials

The point indicates which results and materials relating to the study should be kept in suitable facilities for the time indicated by the competent authorities.

You cannot find the ideal chamber for your test?

Create your own environment, according to any test requirement

The FDM Climatic Chamber

FDM - Environment Makers is a company with over 70 years of experience behind it and its technicians build laboratory instruments approved by all international standards.

The climatic chambers carry out indispensable tests on a wide range of materials and products in order to guarantee their homologation to international standards.

Our climatic chambers are equipped with the most modern technologies such as the stillFACE controller and the revoFACE programmer that assist the operator in all phases of the test, helping him to implement good laboratory practices.

Would you like to receive a quote or do you have questions about the product?

Contact us to receive more information about this Product.