Humidity is one of the climatic factors to be taken into greater account when testing products and materials. Moisture control is critical in most tests but there are some that focus on specific moisture damage and under specific conditions.

This is the case with the Moisture Sensitivity Level Test or MSL Test.

What is meant by Moisture Sensitivity Level?

The Moisture Sensitivity Level is calculated using a scale of values ranging from 1 to 6 and which indicate the level of sensitivity from damage caused by the absorption of humidity.

However, it is not a scale that applies to all moisture damage to all types of products and materials.

Instead, it is designed for a specific product type, i.e. conductors and semiconductors, and calculates the damages of a particular damage process due to humidity.

Let's see it better.

Perform

Extreme Testing

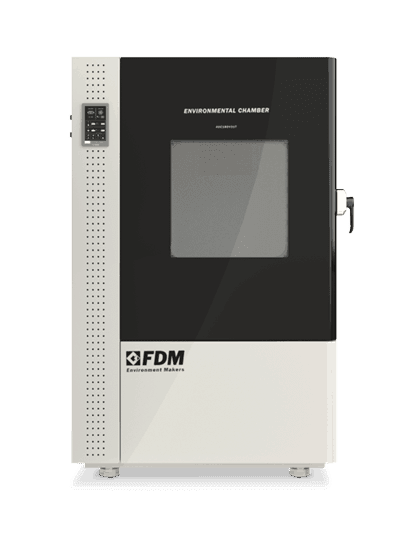

Discover the new series of Environmental Chambers for controlled climate testing

What is the Moisture Sensitivity Level Test for?

Semiconductors and electronic components can absorb humidity in different quantities depending on how they are built and how they are positioned inside the device.

When the moisture trapped inside the semiconductor is released it can cause a variety of damage ranging from small cracks to full-blown semiconductor explosions which are called the “popcorn effect”.

The MSL Test is used to establish the degree of moisture absorption of a component under examination and then assign it a value ranging from 1 to 6 on the sensitivity scale.

Depending on the value, the component will need periodic "baking" phases, i.e. cooking and dehumidification in order to guarantee it a longer life cycle.

But what is baking?

Since it is part of the test itself, we will find out in the next paragraph.

How the Moisture Sensitivity Level Test Works according to J-STD-020

The procedure for the Moisture Sensitivity Level Test is defined within an internationally relevant standard, the J-STD-020.

The MSL Test consists of several phases.

The sample is initially subjected to a visual and microacoustic inspection in its normal conditions. It is then subjected to a 24-hour baking phase at 125° degrees to completely dehumidify.

It is then subjected to the reverse process of humidification to then observe a series of successive releases of the trapped humidity and finally evaluate how much damage it has suffered.

Depending on the result, the sample is placed on a scale from 1 to 6 and indicates its level of sensitivity to moisture damage.

The FDM Oven for the Moisture Sensitivity Level Test

As we have seen, the baking phase is central both in the MSL Test and in the subsequent periodic reconditioning to which the components will be subjected.

To bake semiconductors professionally and in accordance with international standards, there is no better tool than a laboratory drying oven.

FDM laboratory drying ovens are able to perform the baking phase, the MSL Test and many other climatic tests that require reaching and maintaining extreme temperatures.

For further needs, please do not hesitate to contact us.

Would you like to receive a quote or do you have questions about the product?

Contact us to receive more information about this Product.