We are surrounded by sealed containers. From those of consumer products, up to more important components such as pipes, tanks and technical instrumentation which must guarantee a total degree of hermetic sealing.

But how do we know that they are actually hermetic?

This is what the hermeticity testing does.

What is hermeticity testing for?

Hermeticity testing is a procedure used to check the ability of a container, such as a tank, pipe or piping system, to withstand internal pressure without leaking liquid or gas.

Hermeticity testing can be done in a variety of ways, including pressurization with gas or liquid, and using test methods such as static pressure or dynamic pressure.

Regardless of the method, the first distinction to be made is between hermeticity testing for fine leaks and for gross leaks.

Perform

Extreme Testing

Discover the new series of Environmental Chambers for controlled climate testing

The types of Hermetic Testing

As the name suggests, the difference between fine leaks and gross leaks is quantitative.

To determine the size of the leak, calculate the volume of air passing through the leak each second with a pressure difference of 1 atmosphere.

Leak rates greater than 1x10-5 atm-cc/sec are considered gross leaks; those lower than 1x10-5 atm-cc/sec are considered fine leaks.

Typically, fine leak tests uses liquids and gross leak tests uses tracer gases, but there are procedures that use helium as a tracer even in fine hermeticity testinging.

Finally, there is another class of tests that use penetrant dye, both to detect gross leaks and to detect fine leaks. In the latter type of test, a pressure chamber is also used, which we talked about here.

The most common procedures for carrying out hermeticity testing are outlined by the United States Military Standard, a regulatory body of the US military which is taken as a model by the international community with regard to some tests on materials.

Specifically, the most followed standards are: MIL-STD-202-112 and MIL-STD-883, method 1014.

The Climatic Chamber for hermeticity testing

Finally, it is not uncommon for climatic chambers to play a part in the procedure surrounding the actual hermeticity testing.

Climatic chambers can be used in some hermeticity testings when it is necessary to test the resistance of containers to changes in temperature and humidity. In these cases, the sample, the object in question, is first placed inside a climatic chamber where it is possible to modify the environmental parameters, above all the temperature and relative humidity but also the sun exposure or the simulation of rainfall.

In this way, it is possible to reproduce more realistic conditions to which certain types of containers will be exposed, such as those designed for extreme environments - think of pipes that pass at considerable underwater depths.

You cannot find the ideal chamber for your test?

Create your own environment, according to any test requirement

The FDM Environmental Chamber for hermeticity testinging

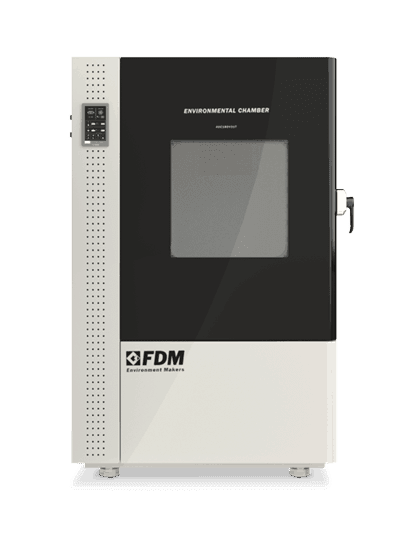

The environmental chamber is a type of climatic chamber meant for extreme testing.

When carrying out the hermeticity test, we recommend the use of this type of chamber which covers all possible environmental conditions and is able to verify how our packages will react even when exposed to the most hostile conditions.

All FDM environmental chambers meet the international requirements for climatic tests and are suitable for reproducing the ideal setting for performing the hermeticity testing.

For further doubts and questions, please do not hesitate to contact us.

Would you like to receive a quote or do you have questions about the product?

Contact us to receive more information about this Product.