Product and material testing plays a crucial role in ensuring the quality and reliability of many of the objects that surround us in daily life. Different criteria can be used to distinguish between the various types of tests on products or materials such as, for example, the industries involved, the technologies used and the parameters that intervene during the test.

One of the most important distinctions, however, is between Non-Destructive Testing (NDT) and Destructive Testing.

In today's article we will deal with Non-Destructive Testing, their importance and, finally, what distinguishes them from Destructive Testing and their mutual advantages and disadvantages.

What are Non-Destructive Testing used for?

Non-Destructive Testing (NDT) is a set of laboratory procedures used to evaluate the quality, integrity and characteristics of materials and products without causing damage to them.

These techniques are fundamental in many sectors, from manufacturing to aerospace. The industries involved range from shipbuilding and automotive construction to civil engineering and the production of electronic components, sectors in which it is important to continuously carry out tests on components already in use, without damaging them.

Perform

Extreme Testing

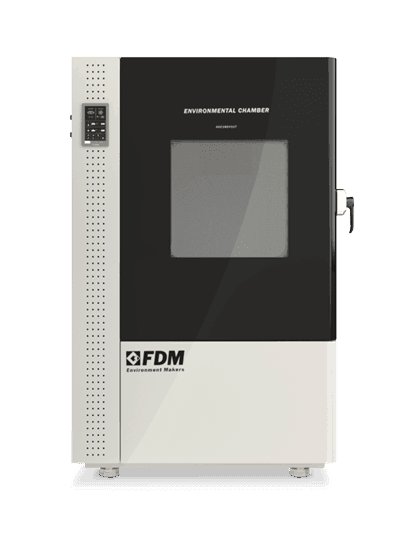

Discover the new series of Environmental Chambers for controlled climate testing

What are Non-Destructive Tests

So what are these tests that are able to test products without causing any damage?

NDTs must be able to detect defects, imperfections and variations in material properties that could affect safety and performance.

Non-invasive technologies are therefore used, mostly for screening and imagining such as:

- radiography

- magnetoscopy

- laser

- ultrasonic control

- penetrating liquids and gases

For example, in the aerospace industry, ultrasonic testing is often used to detect defects in critical components, ensuring flight safety.

Non-Destructive Testing is regulated by ISO 9712:2012.

Differences Between Non-Destructive Testing and Destructive Testing

We now have to talk about the other half of the sky, Destructive Testing, to better understand what the advantages of Non-Destructive Testing are and what the disadvantages are.

Destructive Tests include all those tests that alter, damage or destroy the product or material under examination in order to test its safety and effectiveness. They are a broad category of tests, which include, for example, the environmental tests that we often address on these pages.

These tests are very widespread and absolutely fundamental in the world of testing on products or materials because they allow for greater in-depth analysis than Non-Destructive Testing and produce more easily interpretable data. Why?

Trivially: if I can investigate an object until I destroy it, I will clearly obtain more information.

However, they also have a higher cost and obvious limitations. Destructive tests can only be carried out on prototypes and often before the product is put into production, to avoid unpleasant surprises once production has already started.

On the other hand, Non-Destructive Testing (NDT) can be performed not only after production has already started, but even on products and components already in use.

This is why both types of tests are fundamental and have their own fields of use.

You cannot find the ideal chamber for your test?

Create your own environment, according to any test requirement

The FDM Environmental Chamber for Destructive Testing

As we said, environmental testing is among the most popular destructive tests in the industry.

Almost all products and materials must be tested against the most common environmental parameters, such as relative humidity and temperature, up to their "failure case", to ensure their safety and effectiveness.

The environmental chamber is the most suitable laboratory instrument for carrying out environmental tests, including "extreme" ones which touch very significant values of both temperature and relative humidity.

For further doubts and questions, please do not hesitate to contact us.

Would you like to receive a quote or do you have questions about the product?

Contact us to receive more information about this Product.