Did you know that gasses of different nature are trapped inside many materials and these can be released into the air under certain conditions?

Outgassing is the name that this phenomenon takes and today we are talking about the importance of the outgassing test in some industrial sectors.

What is Outgassing

Outgassing is defined as the gradual release of gas previously trapped inside a material, due to factors such as humidity, heat and low pressure.

Not all materials are subject to outgassing in the same way.

The materials most susceptible to outgassing are solvents, plasticizers, resins, adhesives, paints and polymers; while metals are among the least susceptible.

The dividing line is the molecular structure of the material: the more compact and stable it is, the less it will release gas when subjected to extreme environmental conditions.

Perform

Extreme Testing

Discover the new series of Environmental Chambers for controlled climate testing

Why Outgassing is Important.

Outgassing is of critical importance in the aerospace industry for two reasons.

First, because environments with low pressure and extreme temperatures - such as those of a spacecraft - are the ideal conditions to trigger the phenomenon.

Secondly, because the particles released by outgassing can interfere with the electronic equipment necessary for vehicle operation.

For this it is necessary to subject many components of the aerospace industry to the outgassing test

What is the Outgassing Test used for and how it works.

We have seen that all materials are subject to outgassing to some extent but some types less than others. The outgassing test serves to further deepen this knowledge and find out which of the plastics, polymers, solvents, adhesives and paints that will necessarily be used in the construction of the vehicle are those that will release the least gas.

The test consists of two phases.

First, the sample to be tested is placed in a thermal vacuum chamber or in an environmental chamber, i.e. isolated environments in which the parameters of temperature, relative humidity and atmospheric pressure will then be altered.

Subsequently, the released gasses will be studied by infrared spectroscopy or mass spectroscopy to precisely determine the quantity and quality of the gases in question.

In this way it will be possible to choose the materials with the lowest gas release per surface area.

The main international standard outlining commonly used procedures for performing outgassing testing is ASTM E595.

You cannot find the ideal chamber for your test?

Create your own environment, according to any test requirement

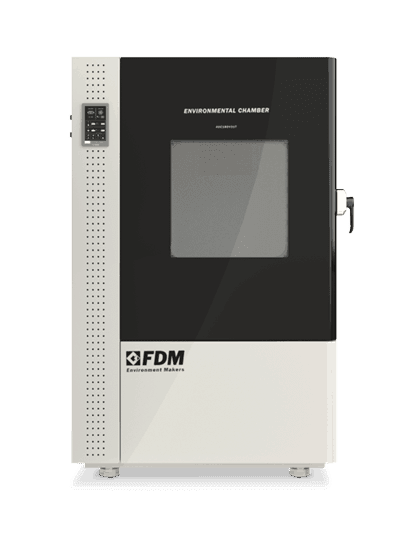

The FDM Environmental Chamber for the Outgassing Test

The outgassing test procedures require very high temperature and relative humidity values, such as exposure to 125° for 24 hours and the same amount at 50% relative humidity.

For this reason, there is no better tool than the FDM environmental chamber, specialized in so-called extreme climatic tests.

On the other hand, to test the pressure, the thermo-vacuum chamber we talked about here is required.

For further doubts and questions, please do not hesitate to contact us.

Would you like to receive a quote or do you have questions about the product?

Contact us to receive more information about this Product.