In the world of product and material testing, many acronyms are used which can be obscure.

The situation gets complicated when these acronyms look alike and indicate tests that have many similarities but also key differences.

This is the case of HALT/HASS testing that we will try to explain in this article!

HALT/HASS Testing: What are they for?

HALT stands for Highly Accelerated Life Testing and HASS for Highly Accelerated Stress Screening. Both consist of a series of tests that aim to accelerate the effect of environmental and mechanical factors on products and materials in order to verify how they react.

In this sense, they are not individual tests but rather procedures that include various tests, some climatic and other mechanical, to be carried out according to international standards.

Some of the more commonly used standards are as follows: IEC 60749-15 and MIL-STD-883 Method 101 for HALT Testing and MIL-STD-883 Method 1014 for HASS Testing.

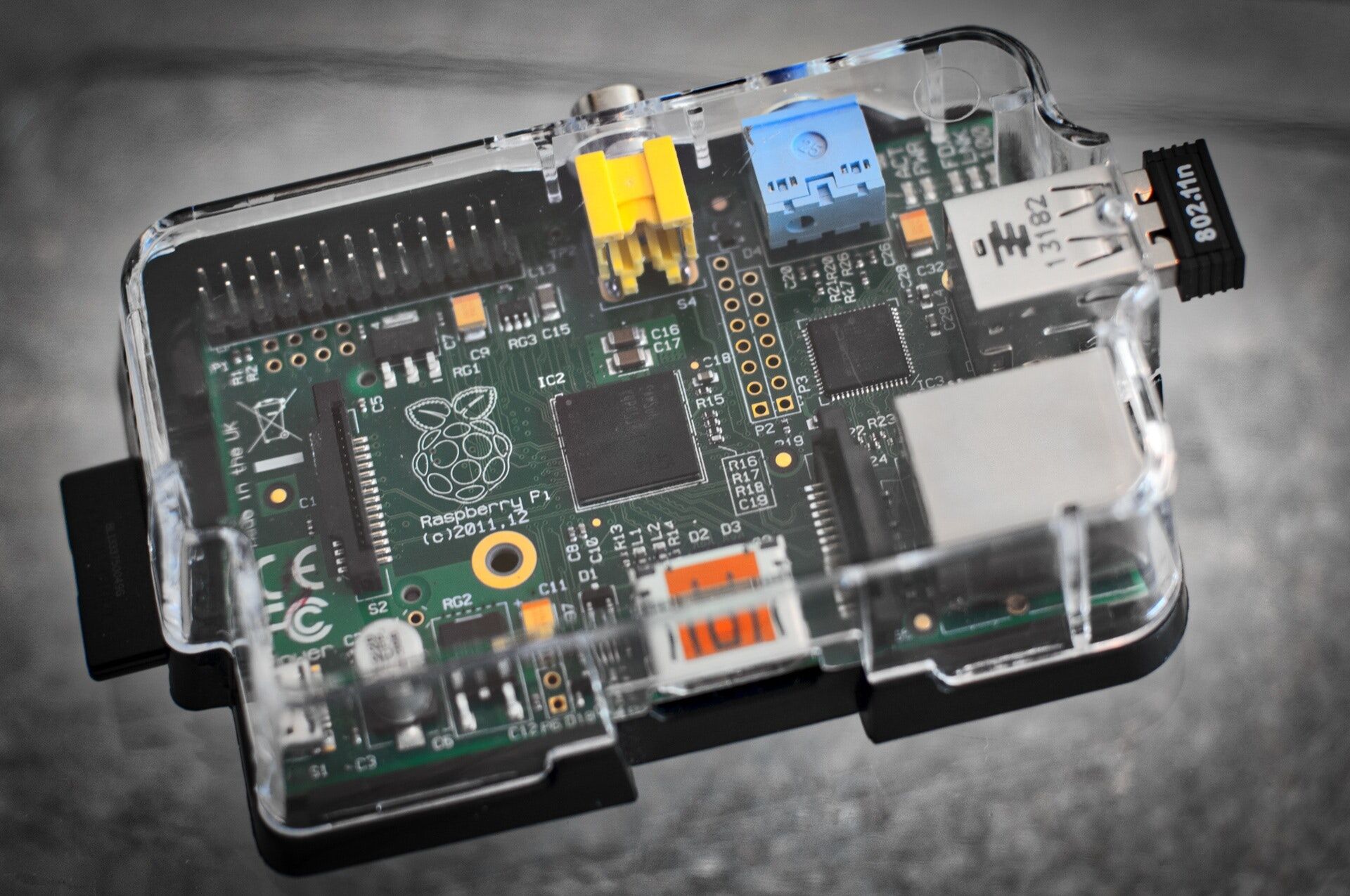

Anyone familiar with international standards will have already noticed that the sectors most involved in HALT/HASS Testing are electronics and aeronautical and military engineering.

The reason is obvious: it is essential in these sectors to ensure that each component is reliable, precise and resistant because any malfunction or design defect can have serious consequences, and not just economic ones.

Perform

Extreme Testing

Discover the new series of Environmental Chambers for controlled climate testing

HALT vs HASS: Similarities and differences

As we have already said, HALT/HASS testing both consist of an ordered series of tests, climatic and mechanical, which "accelerate" the real conditions that products and materials will face in order to verify their behaviour.

Both are fundamental in electronics, including consumer electronics but in particular for aeronautical, naval and military use.

However, there are important differences.

HALT Testing is performed in the production phase and aims to discover design defects that must be discovered immediately in order to correct the design and start mass production.

HASS Testing, on the other hand, takes place once production has already started and serves to discover recurring malfunctions and therefore further polish the quality of the product before it ends up being used in other projects or directly into the hands of consumers.

HALT/HASS Testing therefore work together to ensure the highest quality of products and prevent serious economic damage for the producers themselves.

You cannot find the ideal chamber for your test?

Create your own environment, according to any test requirement

FDM Environmental Chamber for HALT/HASS Testing

Among the laboratory instruments that cannot be missing within the HALT/HASS Testing procedures there is undoubtedly the environmental chamber.

This particular type of climatic chamber is specialized in extreme climatic tests, i.e. those which reach very high values of temperature and relative humidity.

Touching similar values is fundamental in testing electronic products, such as the burn-in test we have talked about here and which is central to HASS Testing procedures.

Furthermore, the environmental chambers can be programmed to carry out automated cycles in order to obtain more precise and reliable results in the most complex tests.

FDM environmental chambers can perform all climatic tests related to HALT/HASS Testing and are an essential tool to ensure the quality of your products.

For further doubts and questions, please do not hesitate to contact us.

Would you like to receive a quote or do you have questions about the product?

Contact us to receive more information about this Product.