On these pages we often talk about environmental tests on products and materials.

But a very large and important class of product and material testing is that of mechanical testing.

Mechanical shock and vibration tests are fundamental within this class of tests and today we will see what they consist of.

How Mechanical Shock (and Vibration) Testing works

Mechanical shock and vibration testing share many of their purposes as they form the cornerstone of all mechanical testing of products and materials; but they also have important differences.

Mechanical shock testing is used to evaluate the ability of an object to withstand sudden impacts or the blows that an object could suffer in real situations.

There are various types of mechanical tests, such as drop tests and impact tests. In general the object undergoes a sharp and rapid acceleration or deceleration culminating in an impact.

On the other hand, the vibration test evaluates the consequences of a slight but subtle stress, which we call precisely vibration. There are many situations in the real world that cause vibrations but let's think above all of the transport of goods which subjects them to continuous vibration. In the laboratory that condition is simulated with the use of specific tools.

Perform

Extreme Testing

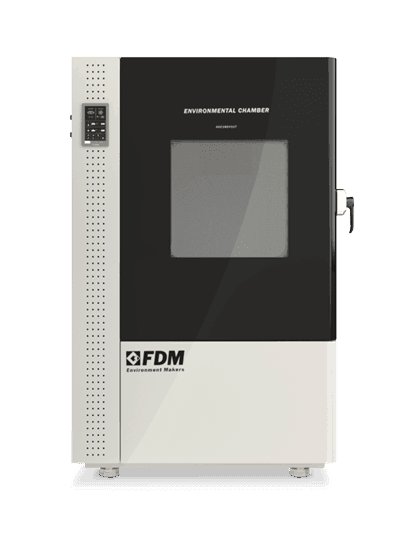

Discover the new series of Environmental Chambers for controlled climate testing

What is the Mechanical Shock (and Vibration) Test for?

Given the universality of the possibility of shocks, as well as the presence of vibrations at least in the transport phase, there really isn't an industrial sector spared from mechanical shock and vibration testing.

However, we can identify three that are particularly invested in it and they are:

- Military and aerospace: for obvious reasons, both military and aerospace vehicles and equipment must demonstrate high resistance to different types of mechanical shocks and very high intensities of vibrations.

- Automotive sector: although less intense, cars are subjected to continuous vibrations and unfortunately also to shocks. Mechanical shock testing, like vibration testing, is among the most important in the automotive industry.

- Electronics sector: for various reasons, electronics are also affected by mechanical shock and vibration tests. Here it is not the frequency or intensity of vibrations and shocks that is at stake but rather the fragility of such sophisticated devices.

The specifications for conducting mechanical shock and vibration tests in each of these sectors are indicated in a series of international standards among which we can mention: MIL-STD-750, MIL-STD-883, ASTM D3332/D3332M, ISO 16750 , and AEC-Q100.

Environmental Chambers and Mechanical Shock Testing

Mechanical testing and climatic testing are the two main categories of material and product testing but they are far from being compartmentalized.

In the real world that these tests try to simulate as accurately as possible, nothing happens in a vacuum. For this reason, many mechanical tests indicate the temperatures in which to perform the test, or rather, in which to condition the sample to be tested.

This is particularly true for the last sector we mentioned, i.e. electronic components which are particularly sensitive to the environmental conditions in which they are found and high temperature and/or relative humidity values significantly affect the reaction of these components to shocks and vibrations.

For this reason, environmental chambers play a role in various procedures in which temperature and relative humidity ranges are indicated within which to keep the sample before testing.

You cannot find the ideal chamber for your test?

Create your own environment, according to any test requirement

The FDM Environmental Chamber for Mechanical Shock Testing

FDM environmental chambers are the perfect tool to condition samples for mechanical shock testing. Especially suitable for the electronics sector where extreme temperature values are required to verify the functionality of the circuits in all conditions.

Furthermore, our technicians are always available to listen to the customer's needs in order to design a customized environmental chamber that meets his needs.

For further doubts and questions, please do not hesitate to contact us.

Would you like to receive a quote or do you have questions about the product?

Contact us to receive more information about this Product.