Storage Covid-19 Vaccine

Ultra Freezer FDM 650 liters

30 boxes capacity

(23x23x20cm)

5,000 units each

Capacity 150,000

total vaccine doses

✓ Security Backup

✓ Password protection touch display

✓ Temperature alarms

✓ Key lock

✓ Remote Monitoring

What is an Ultra freezer?

The Ultra Freezer is one of the main tools used in research laboratories. The ULT freezer safeguards biological samples by keeping them at very low temperatures.

The operating temperature can range from -45°C to -89°C. Several features make an ultra low freezer an extremely reliable solution for laboratory research.

Let us resume them below, thanks to our 50 years experience in the field and our collaboration with some of the most important laboratory researchers throughout the world.

Orientations

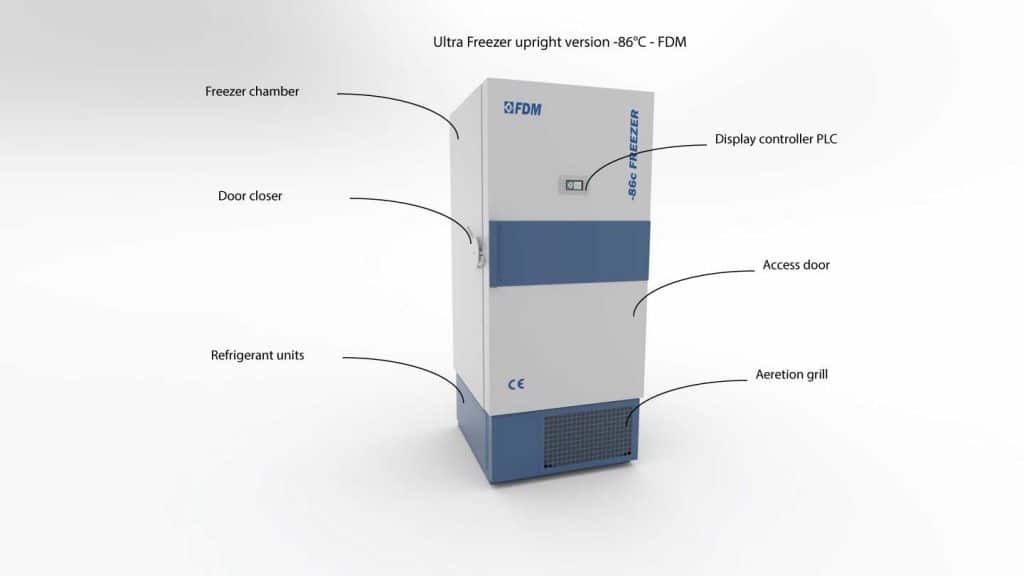

Two versions are generally available: upright freezer or chest freezer with access from the upper part. The most common one is the upright version, as laboratories are increasingly looking to save space to make it easier to move around.

Volumes

The internal storage volume of the low temperature freezer can start from an internal capacity of 200 litres up to a maximum capacity of 800 litres. Some manufacturers, including FDM, can provide customized volumes on requests.

Structure

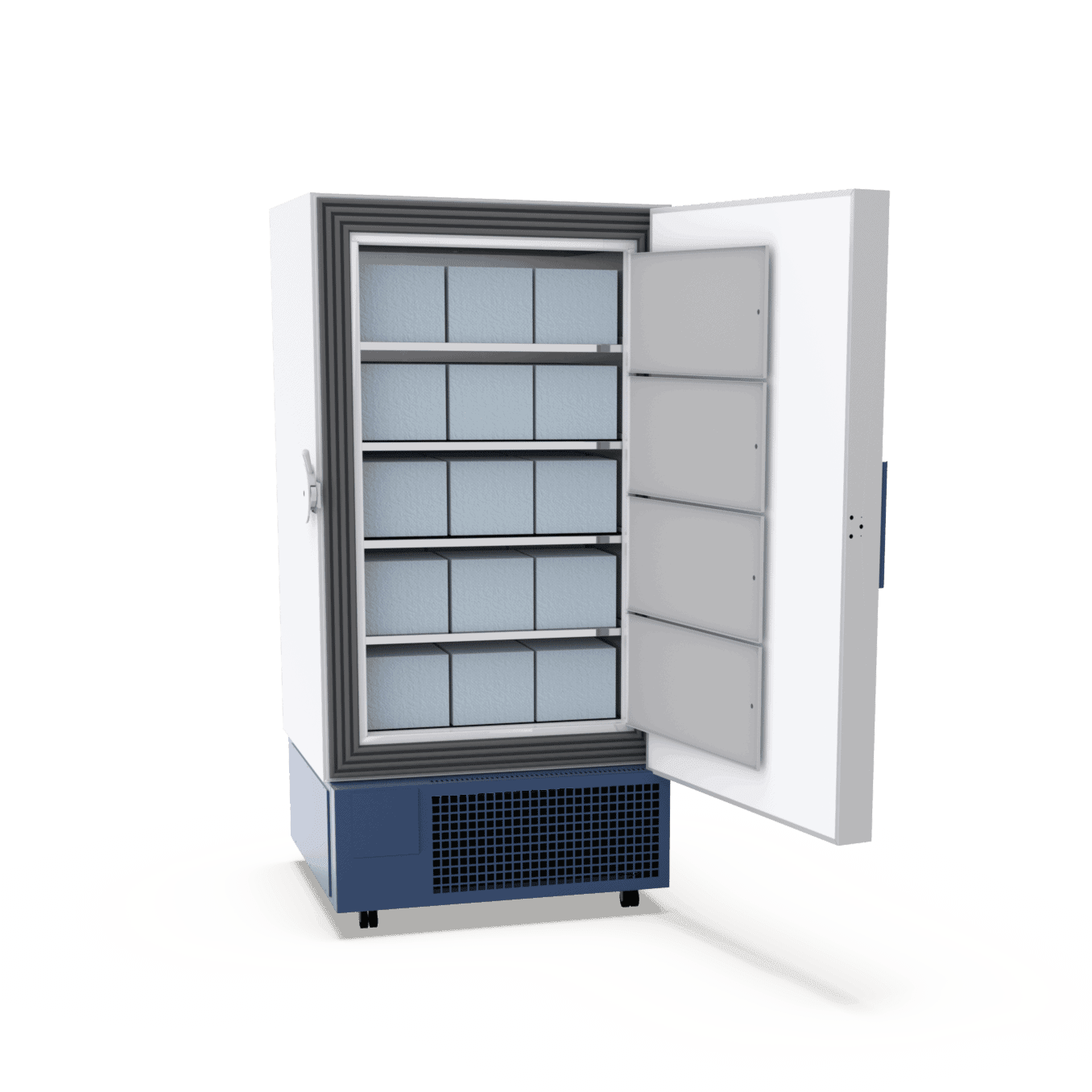

The Ultra freezer has shelves on the inside where research samples are placed. Each shelf is closed by an internal door so to maintain the temperature as uniform as possible on the shelves where no sample is removed or placed.

Insulation

The insulation is an essential part of the Ultra freezer. This polyurethane insulation is free of polluting substances and it is designed to keep the cold stored inside the cabinet, between the external and internal walls. The high insulation coefficient keeps the temperature stable inside the cabinet for hours.

Discover the Ultra Freezers produced in Italy by FDM

Seal

The gasket seal is positioned all along the perimeter of the freezer cabinet. It seals the freezer cabinet when the access door is closed. The most efficient ones are silicone quadruple-step seals, which guarantee even greater temperature stability.

Access door

The main access door also insulated with polyurethane, guarantees to keep the cold, being blocked by an external closure generally fitted with a safety key.

Castors

More practical freezers are equipped with swivel castors at the bottom, to facilitate movement inside the laboratory.

Controllers

The best freezers are equipped with an electronic PLC controller, and a display that indicates freezing parameters. The entire control system is generally equipped with a back-up battery, which ensures that the digital temperature display works even in case of power outages.

How does the refrigerator circuit of an ultra freezer work?

Refrigeration systems can be a single high-power compressor hermetically sealed or two cascade compressors. The two cascade solution, is two refrigeration circuits connected so that the evaporator of one cools the condenser of the other, facilitating the condensation of the compressed gas in the first circuit.

Air-cooled condensers are generally used in laboratory refrigeration systems. They consist of tubular batteries (copper or copper-aluminium) arranged to provide as much surface heat transfer as possible. In Ultra freezers, the circulation of the cooling air is forced by an engine driven fan and the expansion of the refrigerant fluids is obtained by capillary tubes.

Evaporation takes place through steel plate heat exchangers, located inside the chamber, or by means of a coil. In chest freezers, the copper or copper-aluminium coil evaporator is placed along the walls and bottom, while in the upright freezers it runs along the walls and at the top. The coil in the cabinet eliminates the efficiency issue in the heat exchange of freezers with the coil in the insulation cavity.

Refrigerant fluids used in the ULT freezers

Refrigerant fluids are selected from gaseous chemical compounds that can easily be liquefied and characterized by certain properties such as high critical temperature and low critical pressure, limited hazard and toxicity.

They are indicated by the letter R followed by a number that refer to the molecule’s atoms.

Each refrigerant system must be sealed and contain eco-friendly refrigerant HFC gas, free from CFC and HCFC as well as being non-explosive, non-flammable and non-toxic.

The most efficient, environment-friendly refrigerant fluids used in ultra freezers are typically R170, R23 and R290.

With the European Regulation UE 517/2014, the Ultra freezer manufacturers must follow the guideline to allow its use even after 2030. So they must use green refrigerants:

R717 (ammonia)

R744 (Carbon dioxide)

R170 (Ethane)

R290 (CARE 40) Propane

R600a (CARE 10) Isobutane

R1150 (Ethylene)

R1270 (CARE 45) Propylene

R449A (zeotropic HFO)

Find out how FDM is constantly looking for the best refrigerant gases

Which accessories can an Ultra Freezer have?

The accessories generally supplied include:

a CO2 and/or LN2 emergency system (both with independent power supply, probe and battery).

To track room temperature, freezers are optionally equipped with a charted weekly temperature recorder, which have almost completely been replaced by digital ones.

In line with current international standards, the recorder is mandatory for freezers at -45° C and -86° C for the storage of blood plasma.

Other accessories include: various kinds of steel containers, drawers and racks for storage of cryoboxes, microplates, blood plasma and test tubes designed for low and very low temperature storage.

Handling goods inside the ultra freezers requires you to wear suitable protective headgear, leather gloves to protect your hands, overalls and smocks.